Cast iron open-rod wedge gate valve

Cast iron open-rod wedge gate valve

Nominal diameter: DN50-600 mm

Nominal pressure: PN1.0MPa

Suitable temperature: ≤200℃

Applicable medium: Water, steam, oil

Body material: Gray cast iron etc.

Connection form: Flange

Design specification: GB/T 12234

Structural length:GB/T 12221

Connecting flange:JB/T 79

Z41T rising stem wedge gate valve is an automatic valve, which relies on the pressure of media to press the gate sealing surface to the other direction of the valve seat sealing surface, making the two sealing surfaces closely match to ensure the sealing effect.The gate plate of rising stem wedge gate valve can be made into a whole, which is usually called rigid gate plate.Or improve its process, so as to make up for the deviation in the process of processing, this kind of gate is called elastic gate.

1. Z41T rising stem wedge gate valve features:

1. Compact structure, reasonable design, make the valve rigid, unobstructed channel, medium resistance is small;

2. The sealing surface is made of stainless steel and hard alloy, with long service life;

3. The structural type can be divided into various types, such as elastic wedge type single ram or rigid wedge type single ram and double ram, etc.;

4. Choose flexible graphite for packing, with reliable sealing, convenient and flexible operation;

5. Drive mode can choose manual, pneumatic, electric, gear transmission, etc.

2. Standard for Z41T rising stem wedge gate valve:

Design specification: GB/T 12234

Structure length: GB/T 12221

Connecting flange: JB/T 79

Test and inspection: JB/T 9092

Pressure-temperature: GB/T 9131

Product identification: GB/T 12220

3. Z41T rising stem wedge gate valve main technical parameters:

| Type | PN | Nominal pressure/MPa | Suitable temperature/℃ | Applicable medium |

| Z41T-10 | 10 | 1.0 | ≤200 | Water, steam |

| Z41W-10 | 10 | 1.0 | ≤100 | Oil |

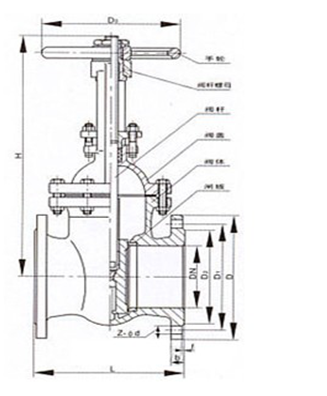

4. Z41T rising stem wedge gate valve

| Type | Material | |||

| The body,Cover,Ram | Stem | Sealing surface | Packing | |

| Z41T-10 | Gray cast iron | carbon steel | Brass | Oil-impregnated asbestos packing |

| Z41W-10 | Gray cast iron | carbon steel | Gray cast iron | Oil-impregnated asbestos packing |

5. Z41T rising stem wedge gate valve dimensions:

| DN | L | D | D1 | D2 | b | H | H1 | z×Φd | D0 | Weight/kg |

| 50 | 180 | 160 | 125 | 100 | 20 | 286 | 345 | 4×Φ18 | 180 | 17 |

| 65 | 195 | 180 | 145 | 120 | 20 | 331 | 410 | 4×Φ18 | 180 | 22 |

| 80 | 210 | 195 | 160 | 135 | 22 | 375 | 470 | 4×Φ18 | 200 | 30 |

| 100 | 230 | 215 | 180 | 155 | 22 | 430 | 544 | 8×Φ18 | 200 | 35 |

| 125 | 255 | 245 | 210 | 185 | 24 | 523 | 660 | 8×Φ18 | 240 | 52 |

| 150 | 280 | 280 | 240 | 210 | 24 | 592 | 762 | 8×Φ23 | 240 | 70 |

| 200 | 330 | 335 | 295 | 265 | 26 | 772 | 993 | 8×Φ23 | 320 | 125 |

| 250 | 380 | 390 | 350 | 320 | 28 | 903 | 1176 | 12×Φ23 | 320 | 170 |

| 300 | 420 | 440 | 400 | 368 | 28 | 1043 | 1366 | 12×Φ23 | 400 | 226 |

| 350 | 450 | 500 | 460 | 428 | 30 | 1173 | 1540 | 16×Φ23 | 400 | 360 |

| 400 | 480 | 565 | 515 | 482 | 32 | 1245 | 1765 | 16×Φ25 | 500 | 444 |

| 450 | 510 | 615 | 565 | 532 | 32 | 1500 | 1970 | 20×Φ25 | 500 | 590 |

| 500 | 540 | 670 | 620 | 585 | 34 | 1780 | 2280 | 20×Φ25 | 720 | 740 |

| 600 | 600 | 780 | 725 | 685 | 36 | 2010 | 2620 | 20×Φ30 | 720 | 960 |